A Q&A with Andrew Thomas, Sustainability Engineer and Recycling Fund Manager for the University of Warwick

We spoke to Andrew Thomas, Sustainability Engineer and Recycling Fund Manager for the University of Warwick about how the university is working to drive carbon reduction in line with their 2030 net-zero target.

What is your background in relation to energy efficiency and how did you get into the sector?

I have a degree in Mechanical Engineering from Warwick University (from many years before I started work here!) My first job after graduating was for a very small company involved in the development of a water purification technology that Russian scientists developed for the Mir space station. With only six people we all had to pitch in with whatever was needed, and we spent a lot of time on patent submissions and dodging the interests of multinationals!

Remaining in the water industry I spent a number of years designing and managing the installation of water features in leisure centres, water parks and municipal installations. This sparked my interest in how buildings work and use energy but has also given me some insight into the workings of specialist contractors, similar to those that we employ in my role now.

In 2009 I was ready for a career change and wanted to pursue my interest in buildings and sustainability, so I completed an MSc in Low Carbon Building Design at De Montfort University. Shortly after graduating, a job as a Utilities Technician came up at the University of Warwick. The role gave the opportunity of working in the energy sector but beyond the “building” and looking at the surrounding infrastructure too – I jumped at it.

Could you tell us a bit about your role within your organisation?

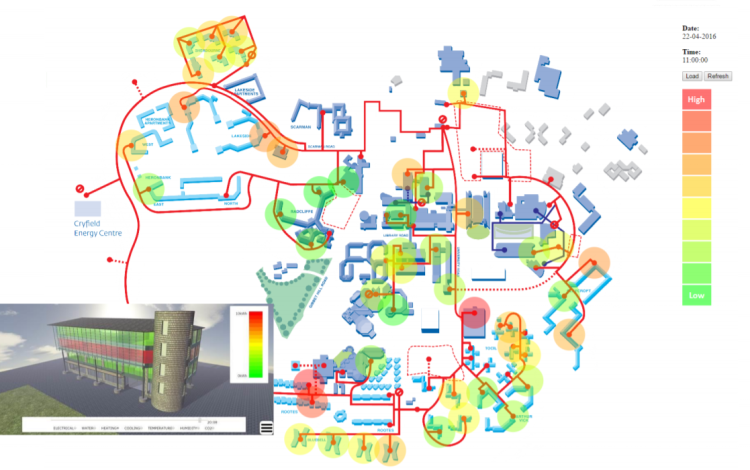

My role involves carbon planning, so I am currently working on the detail of the University’s carbon plan towards our 2030 net-zero target. I help identify energy-saving opportunities for the University, which involves looking at large amounts of data, understanding how buildings work and what happens inside them and looking for opportunities to reduce energy. I work on capital projects by setting targets, monitoring progress and supporting life cycle costing analysis. I support the management of our energy infrastructure, which includes monitoring and supporting the Operations team with the running of our Energy Centre and District Heating infrastructure.

Could you give a quick overview of the number of sites at the University and current energy spend? How has this energy spend changed/reduced over the time you've been with the University and how much of a driver were the HEFCE targets in this change?

The University has two main sites with approximately 500 buildings, the majority of which are at our site on the South West of Coventry. Our current energy spend is circa £9.4m which compares to around £8.3m when I joined 10 years ago (not adjusted for inflation). In that time, however, our staff and student numbers, floor area and annual income have grown by 29, 17 and 43% respectively. This suggests we’re doing a lot more with the same but absolute reductions are challenging. HEFCE prompted the writing of the University’s 2010 carbon plan so I’d say they were a significant driver.

How do you identify new projects?

Metering data, talking to engineers and project managers across the capital programme and maintenance departments, and our network of lab technicians and Green Champions (staff and students who are passionate about sustainability).

How do you procure for consultants and suppliers?

Generally fixed term on frameworks for repeated work. For a one-off supply of specialist equipment or services the project manager selects three or more capable suppliers based on their ability to deliver, past experience at the University, if available, and testament of others (I find the AUE network useful here). We then develop a tender specification and work with our procurement team to decide on the evaluation criteria. We are lucky in the Estates department to have a procurement team who then support us through the whole process of engagement with the suppliers, evaluation and eventual appointment.

What projects have you taken the most pride in?

It was our small team that secured the funding for a significant expansion in our combined heat and power capacity in 2014 which was rewarding and saved significant carbon while grid electricity emissions were higher. I also take pride in some of my earlier projects where I was involved in every step of the project – writing the business case, doing the design drawings, writing the tender specifications and managing the installation through to commissioning. These earlier projects included conversion of fume cabinets to variable air volume (a SALIX RGF funded project) and upgrading ventilation plant to demand control systems across many buildings (a SEELS 4 funded project). I do less of this now as we need to turnover greater numbers of projects – but it was rewarding.

What is your biggest challenge to delivering and identifying projects?

Identifying projects tends not to be a problem. Developing them into viable proposals that fit with a constantly changing University takes more time. With regard to delivery, as with all large growing organisations, there are a great many things that need to be done (to develop the facilities to enable top-class teaching and research, to improve facilities to be more efficient, comfortable, and inspiring etc.) We do a lot at the University but eventually, there are constraints on the resource and practicality of delivering large volumes of projects.

What technologies do you have the most expertise?

We inevitably end up as “Jacks of all trades” in our field so I know a little bit about quite a lot of things (the general workings of Autoclaves is something I learned this week!). But I suppose CHP, DH networks, PV and ventilation (including laboratories) are areas that I’ve really gone into some depth on.

You have consistently used the funding available in your RF, what key advice would you give to other fund managers wanting to follow in your success?

Not everyone is a natural salesperson, but you need to promote the fund with your capital project managers, maintenance teams, lab managers – anyone who is involved in making decisions that impact energy consumption. Generally, people want to make things better and eventually people start coming to you with projects. Try not to baffle people with the workings of the scheme if they don’t need to know it.

What technologies do you see as the big players for hitting the future carbon reduction targets of the University of Warwick?

Decarbonisation of heat is key. Heat pumps powered by renewable energy are the obvious contender here, but the electrification of transport will be competing for limited quantities of available renewable electricity. There are obstacles to overcome in both the heating and transport sector, so I feel we’re at an interesting juncture.

How has the University responded to COVID-19 regarding your carbon reduction targets and energy efficiency projects?

The 2030 target has not changed. In the shorter term, the financial uncertainty that COVID-19 has caused means our capital program will slow down as we wait to see how things develop. This means our carbon reduction will change the emphasis to efficiency and ensuring what we have is working as well as it can. We’ve learnt a lot about our buildings and how well-automated systems work since lockdown begun and we have a great opportunity to ensure that these systems are recommissioned properly as we begin to re-occupy.