Leed-ing the way to a more sustainable future

How a historic government scheme has supported progress towards net zero at Leeds Beckett University.

Located in the north English county of Yorkshire, Leeds Beckett University educates more than 23,000 students a year. Renowned for its sustainability research, the university aims to embrace its leadership role in carbon reduction to pave the way to a more sustainable future.

Striving to become a net zero campus by 2035, the university has been working to reduce the emissions associated with its estate for nearly two decades.

Tarik Jacob, university energy manager, said: “As one of the top employers in Leeds, Leeds Beckett University embraces its role as a trailblazer in carbon reduction.”

As one of the top employers in Leeds, Leeds Beckett University embraces its role as a trailblazer in carbon reduction.

Key to progression against this target, say university representatives, is using data to inform the prioritisation of works. Through analysing its buildings to see which buildings were putting the largest load on the electrical and gas heating systems, the team was able to make headway through upgrades across its vast estate.

In the initial years, projects largely focused on efficiency upgrades. Energy efficiency upgrades support a building to reduce its overall energy demand when performing the same task and achieving the same result. Notable projects included LED lighting upgrades, heating system improvements and enhanced hot water controls. The university credits the England Recycling Fund for acting as a key financial enabler to get these projects off the ground.

Tarik added: “By meticulously analysing electricity and gas usage through metering and continuous monitoring, we’re able to unlock energy-saving opportunities.

“The recycling fund has been a lifeline, propelling projects that might otherwise have struggled.”

The recycling fund has been a lifeline, propelling projects that might otherwise have struggled.

Since fund inception in 2008, the university has utilised its recycling fund to a value of approximately £1.1 million across 50 sustainability projects. We deliver funding for this scheme on behalf of the Department for Energy Security and Net Zero.

Collectively, these projects have reduced the university’s carbon emissions by 2,000 tonnes. A 2,000 tonne reduction in carbon emissions is equivalent to a per-passenger air travel emission distance of one million miles – enough to fly you from London to New York 289 times*.

Additionally, experts estimate they are collectively saving the university £870,000 in annual energy bills.

Tarik added: “By embracing cleaner energy sources, the university is actively reducing its carbon footprint and leading by example.

“The benefits realised have led to additional internal funding for energy initiatives, resulting in a remarkable 65% reduction in scope 1 and 2 emissions compared to our 2009/10 levels.”

Scope 1 and 2 emissions relate to emissions directly within an organisation’s control and include the generation of purchased energy from the grid. Organisational net zero targets are usually tied to their scope 1 and 2 emissions, with scope 3 emissions attributed as ‘indirect’ emissions associated with upstream and downstream activities of an organisation.

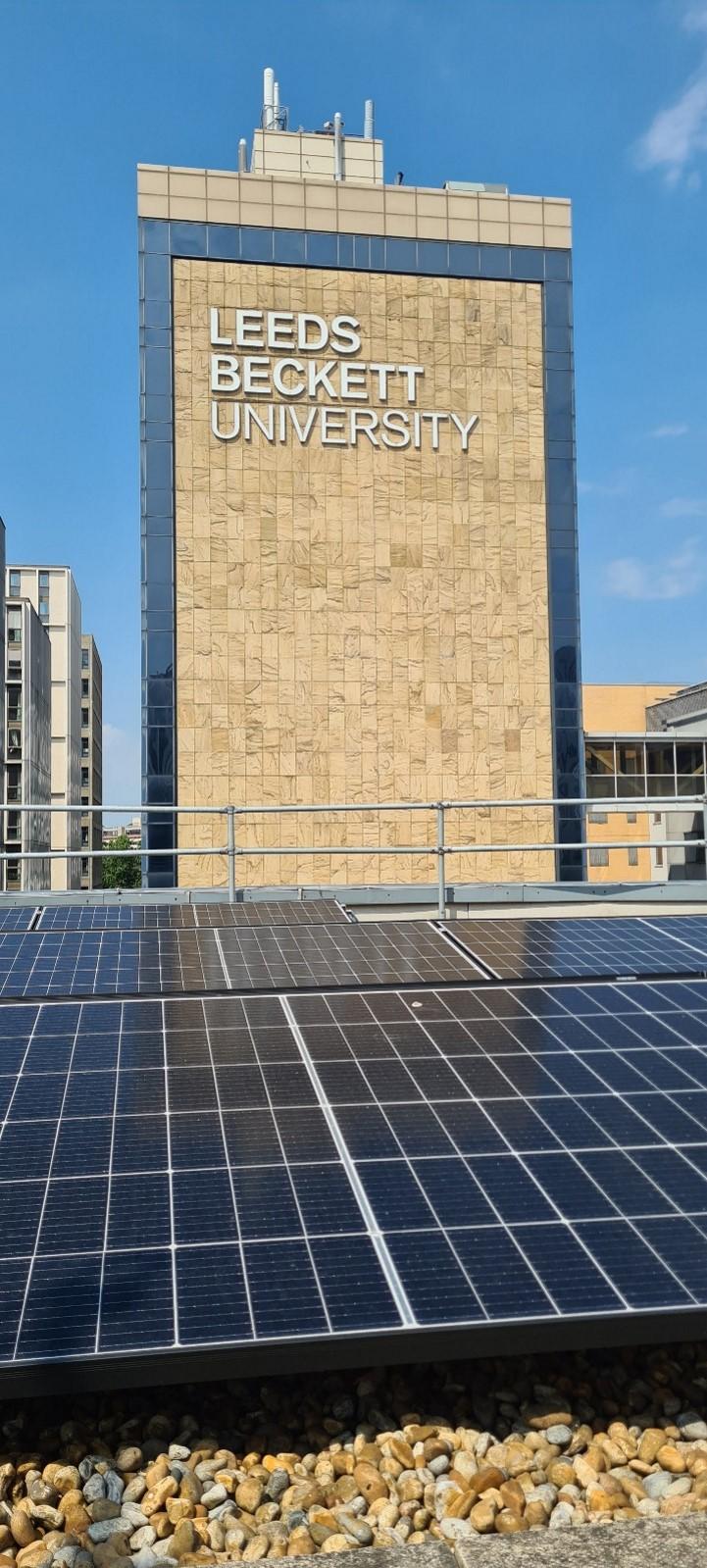

With the recycling fund coming to a close in March 2025, the university has completed its final project funded through the scheme: a solar PV installation on the iconic Rose Bowl building. Located on the city campus in the centre of Leeds’ business community, the Rose Bowl is home to teaching spaces, lecture halls, conference facilities and more.

However, the journey isn’t over, with the university now investigating opportunities for further capital works programmes that continue to reduce its environmental impact and further drive progression toward its net zero goals.

Mitch Thomas, our client support officer who has been working with the university, said: “Through these initial projects funded through its recycling fund, Leeds Beckett University has built a strong foundation upon which it plans to accelerate its decarbonisation journey.

“The collective outcomes associated with what may, in isolation, be viewed as ‘smaller scale’ capital works programmes indicates the importance of these measures and the true value in a whole building approach when looking at larger projects such as heat decarbonisation.”

The collective outcomes associated with what may, in isolation, be viewed as ‘smaller scale’ capital works programmes indicates the importance of these measures and the true value in a whole building approach when looking at larger projects such as heat decarbonisation.

About the England Recycling Fund

- The England Recycling Fund is a loan-based, ring-fenced fund, created with capital provided on behalf of the Department for Energy Security and Net Zero through Salix, and matched by the public sector organisation. It encourages organisations to re-invest financial savings that result from projects into further decarbonisation and energy efficiency projects, thus operating in a cyclic “recycled” manner.

- The scheme has been closed to new applications since 2010. However, since that time we have continued to support organisations with open funds to complete thousands of projects worth more than £267 million through the scheme.

- The average fund has been recycled more than three times, and, when combined, our recycling fund projects save over 296,000 tonnes of carbon emissions every single year.

- The fund is closing at the end of the 2024/25 financial year, with any projects funded through the scheme required to complete by 31 March 2025.

Solar installed at Leeds Beckett University.

Credit: Leeds Beckett.

*Carbon calculations have been generated through a tool created by our carbon and technical experts here at Salix. The intention is to provide carbon savings estimates to aid with a common understanding of emission data and statistics. These estimates are approximate; it is not recommended to use this tool for formal carbon emissions analysis. The tool uses UK government conversion factors alongside emissions estimates sourced from various studies, but it is possible a margin of error may exist. For more information about the formulas and methodology used in this tool, please contact us at [email protected]. E&OE.