Key checks and supporting information required for heat network applications

-

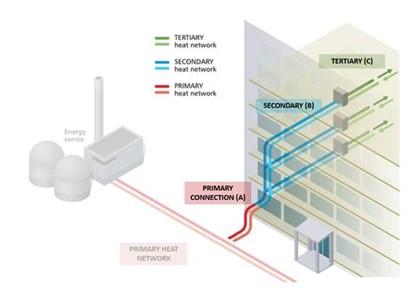

details of the heat network you intend to connect to

-

which generation of heat network is being used?

-

details of the building fabric showing that it is suitable for this measure

-

heating system sizing calculation based on building peak heat loss

-

calculations evidencing the heat loss figures for the primary pipework connecting the building to the energy centre

-

schematics and drawings of existing and proposed system

These network design drawings should clearly demonstrate the pipelines to be funded by the Public Sector Decarbonisation Scheme.

-

flow and return temperatures for existing and proposed system

-

water flow rate for existing and proposed system

-

show that the proposed pipework and pumps are suitable for the required flow rate

-

show that the heat emitters have been sized for the flow temperature set out

- details of current heat emitters

- details of proposed heat emitters

-

bespoke carbon factor calculation for the heat network

-

design considerations for how thermal losses across the network will be minimised, including pipe insulation

-

cost evidence including connection fees, standing charges and variable fuel rates

-

consideration of how legionella will be controlled

-

evidence that the new connection will be operational by the grant end date